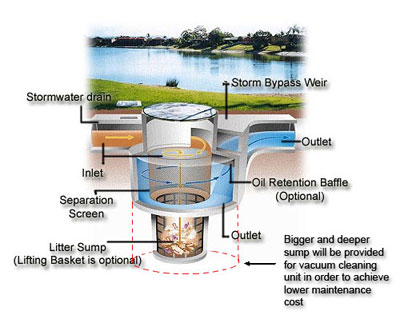

- Polluted Runoff

- Stormwater

(with trash & debris)

- Separation Chamber

(water flows through trash & debris drop down)

- Solid collection Sump

(trash & debris)

- Stormwater

(water only)

- Unpolluted Waterways

EcoClean CDS Gross Pollutant Traps

Gross Pollutant Traps or GPTs are structures designed to remove litter, debris and coarse sediment from storm water. Only few types of gross pollutant traps, such as our Ecoclean CDS Gross Pollutant Traps and CleansAll Gross Pollutant Traps are designed to remove all types of gross pollutants, including sediment, oil and grease effectively from storm water.

Ecoclean CDS Gross pollutant traps may also be used as pretreatment for flows into a pond or wetland to confine and trap the sediment for easy removal, thus protecting the lakes and waterways from being polluted by gross pollutants and sediment. CDS Gross pollutant traps are commonly used to remove both coarse and fine sediment before the flow enters a filtration device such as a rainwater harvesting tank or on-site detention tank to prevent clogging of the filtration device.

What is CDS?

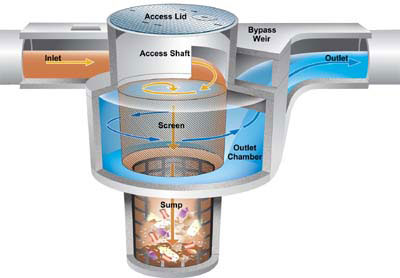

Based on a surprisingly simple combination of Non-Blinding screens and flow management, Continuous Deflective Separation or CDS Technology is a non-powered, low maintenance alternative to traditional direct screening system.

Ecoclean CDS Gross Pollutant Traps are designed to be retrofitted into existing and newly constructed drainage systems. The unit covers a minimum of surface space, with lids specially designed for the location and pre-engineered for traffic loading. Generally located beneath the ground, the unit requires no support infrastructure or power.

Ecoclean CDS Gross Pollutant Trap uses indirect screening to trap even smaller pollutants. A unique, non-blocking screen design deflects particles into a catchment area while clean water flows to the waterway.

An engineered product that has harnessed complex hydrodynamic principles …

… into a simple & cost-effective system that significantly reduces contamination of our waterways

… into a simple & cost-effective system that significantly reduces contamination of our waterways

Advantages of the Ecoclean CDS Gross Pollutant Traps are:

- captures and retains close to 100% of all solid materials, irrespective of flow conditions

- utilises indirect screening, preventing the screen from blinding

- visually unobtrusive

- various unit sizes to suit application and site requirements

- ease of cleaning by means of basket, eduction or utilizing a customized cleaning truck.

Applications:

Storm water

Ecoclean CDS Gross Pollutant Trap has been highly successful in removing pollutants from the storm water system. Some high profile sites within Australia and overseas have used the technology to keep the waterways clear of litter, vegetation and other matter flowing through the storm water systems.Industrial

Ecoclean CDS Gross Pollutant Trap has been of great use to industrial sector. The indirect screening provides a non- blinding separation system for a number of processes. CDS Gross Pollutant Trap has been effectively used in separating pollutants from cooling liquids, sediments from site runoff and washdown facilities.Fine Solid Separation

Ecoclean CDS Gross Pollutant Trap has been specially developed with a high rate process for the removal of suspended solids from sewage. It achieves a stream that is highly amendable to disinfection for the treatment of sewer overflows. It is suitable for reuse in many applications, especially ideal for feeding to biological processes with low particle BODs, COD levels.Sewer Overflows

Sewer overflows have polluted waterways around the world. Ecoclean CDS Sewer Overflow Unit (CSO) has been specially developed to remove gross solids from sewer overflow locations. The gross solids are effectively separated and returned to the sewage systems while the screened fluid is then diverted into the overflow line.Learn About CDS Technology:

Indirect CDS Screening Technology

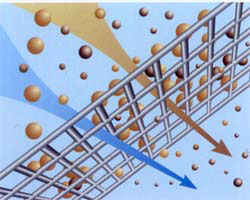

Normal Direct Screening

With normal direct filter screening, particles impact directly on the screen and eventually cause blinding

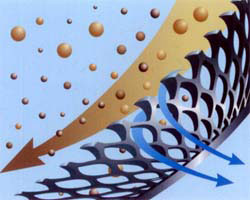

Indirect CDS Screening Technology

With CDS indirect screening, particles sweep past screen which remains clear

CDS World-Class Technology

CDS is the only non-blocking screening technology independently validated by world-class research organizations such as:

CDS Performance

| Description | Capture Rate |

|---|---|

| Gross Pollutants (> 5mm) | 99% |

| Coarse Sediments (> 0.125mm) | 95% |

| Floatable Pollutant | 99% |

| Total Solid Suspension (TSS) | 70%* |

| Free oils and grease in spill situation | 95% |

| Total Phosphate | > 20% |

With longer retention time achieved using one single bigger unit CDS can achieve 3 to 4 LEED points as proven in Malaysia first LEED COLD Green Building SHELL 3 in Cyberjaya.

Methods Of Removal

Eduction (Suction) Vacuum Truck

Eduction (Suction) Vacuum Truck Removable Basket Unit

Removable Basket Unit Materials Grab Truck

Materials Grab TruckLitter Sump Maintenance

- Vacuum Suction

- Installed Basket – Simply lift out pollutants with a crane

- Grab/Clamshell - Using a clamshell type grab bucket

Vacuum & Suction

Vacuum & Suction Installed Basket

Installed Basket Grab/Clamshell

Grab/ClamshellApplications

Stormwater

CDS has been highly successful in removing pollutants from the stormwater system. Some high profile sites within Australia and overseas have used the technology to keep the waterways clear of litter, vegetation and other matter flowing through the stormwater systems.

Sewerage Overflows

Sewer overflows have polluted waterways around the world. CDS has developed a product that removes gross solids from sewer overflow locations. The gross solids are separated and returned to the sewerage system and the screened fluid is then diverted into the overflow line

Industrial

The CDS technology has been of great use to the industrial sector. The indirect screening provides a non-blinding separation system for a number of processes. CDS has been involved in separating pollutants from cooling liquids, sediments from site runoff and washdown facilities.Sizing Criteria

- Catchment Area

- Catchment use and imperviousness leading to pollutant loadings

- Flowrates for the 3 month event

- Performance requirements of the approval authority

- Desired cleaning method and frequency

- Site constraints

- Budget constraints

CDS Unit Selection

CDS Units: Key characteristics

| CDS Model No | Catchment Area (ha) |

Pollution Storage in Sump m3 |

Underground Footprint m |

Ground Level Footprint Diameter m |

|---|---|---|---|---|

| F0506 | ≤ 1 | 0.50 | 1.0 x 1.0 | 0.9 |

| P0708 | ≤ 2 | 1.80 | 1.5 x 1.5 | 1.3 |

| F0908 | ≤ 4 | 2.65 | 1.5 x 1.5 | 1.3 |

| F0912 | ≤ 6 | 2.95 | 1.5 x 1.5 | 1.3 |

| P1009 | ≤ 8 | 3.35 | 2.0 x 2.0 | 1.3 |

| P1012 | ≤ 12 | 3.60 | 2.0 x 2.0 | 1.3 |

| P1015 | ≤ 18 | 3.80 | 2.0 x 2.0 | 1.3 |

| P1512 | ≤ 20 | 7.10 | 2.6 x 2.6 | 1.8 |

| P2018 | ≤ 45 | 19.00 | 3.5 x 3.5 | 2.3 |

| P2028 | ≤ 75 | 21.50 | 3.5 x 3.5 | 2.3 |

| P3018 | ≤ 100 | 28.50 | 6.5 x 6.5 | 3.5 |

| P3024 | ≤ 150 | 32.75 | 6.5 x 6.5 | 3.5 |

| P3030 | ≤ 200 | 37.00 | 6.5 x 6.5 | 3.5 |

| C4527 | 200-250 | 58.50 | 8.0 x 8.0 | 5.0 |

| TWIN | ≤ 500 | variable | variable | variable |

NOTE :

- CDS Model Selection Table shall only be used for initial sizing. Actual CDS model shall be determined by detailed engineering. Please check with EcoClean Technology Sdn Bhd for your specific needs.

- Twin precast unit combination can be used to treat larger flows – detail on request

Key

| P | Precast Concrete |

| F | Fiberglass |

| C | Cast-in-place |

* Based on vacuum suction

- P2018 Precast unit with screen diameter 2000mm and height 1800mm

- F0912 a Fiberglass unit with screen diameter 900mm and height 1200mm

Other Specific Applications ( details on request )

- CDS Surface / Rainwater filtration unit

- CDS Sewer overflow unit (CSO)

- CDS Stainless steel or FRP industrial separator

- CDS Sewer mining process for reuse water

- CDS Smart water (Class A re-use water)

- CDS filternator media filtration system

- EcoClean Ausdrain Stormwater System for rainwater harvesting, re-use, infiltration, on site detention and bio-remediation.

- Ecoclean oil and grease trap.

- EcoSac wastewater primary screening

- Vacuum fluid evacuation system

- CDS Hybrid Advanced Immobilised Cell Reactor Technology (India) for water / Wastewater Treatment.

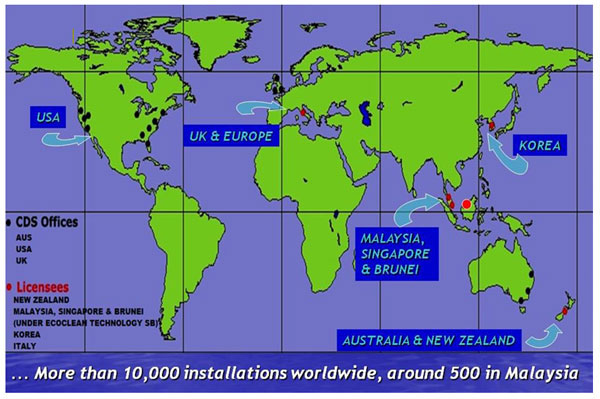

Rapidly Expanding Global Reach

In Malaysia

Urban Stormwater Management Manual for Malaysia

(Manual Saliran Mesra Alam Malaysia)

2000

Volume 13

Treatment Control

Best Management Practices (BMPs)

Gross Pollutant Traps (GPTs)

“…taking into consideration the present problems faced by the nation such as flash flood, river pollution …”

CDS Project Profiles Sample Bill of Quantity